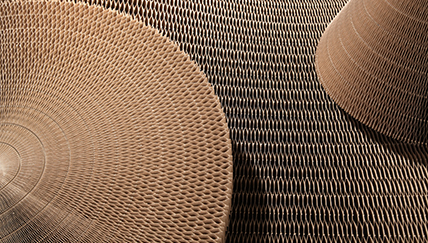

Cardboard paper is used as a substitute for wood chips or particle board, while retaining the required product quality parameters. The attractiveness of paper honeycomb lies in its features: durability, lightness, low cost, cheap and easy transportation.

Uses for paper honeycomb:

Furniture industry

Paper honeycomb is used in the furniture industry as an insert in furniture panels. It is lightweight, resistant to compression, easy to process and does not emit any harmful substances into the environment.

Advantages: it reduces the cost of manufacturing furniture, is easily recyclable, and has a high resistance to compression.

Door manufacturing

Cardboard paper honeycomb is a perfect filler for all types of doors. It can be perfectly adapted to door panels and helps to absorb sound.

Advantages: it reduces the cost of manufacturing a door, and meets the requirements for sound insulation.

Automotive

Cardboard paper honeycomb is used in the automotive industry for the production of interior trim parts in order to reduce their weight and cost.

Advantages: small height and tiny mesh, easy to achieve the desired shape, high resistance to shock and compression.

Packaging production

Packaging made from paper honeycomb is a great product for protecting household and industrial appliances, equipment, and fragile, delicate products against external effects during transportation.

Advantages: it has excellent shock-absorbing properties, does not emit harmful substances into the environment, and is cheaper than similar packaging products.

Quality parameters Download